The continuous tyre pyrolysis machine refers to the latest and the most sophisticated and sound technology available all over the world and which continues to play a leading role in the management of plastic and rubber waste. It can be used to recycle rubber as well as waste oil. It is the most cost effective method designed by experts and technologists vast in automation and recycling process.

Pyrolysis refers to a thermo chemical decomposition of all organic materials when they are subjected to high temperatures. The process will only give the desired results if it is done in the absence of oxygen. It is one of the most commonly used processes for charring. The end products are gas, liquid products and some solid residue rich in carbon. This process is heavily used in industries to produce methanol, activated carbon and other chemical. It is also used to convert biomass into syngas and convert wastes into disposable substances. Also, it is one of the processes that are used to make PVC from vinyl chloride.

The waste pyrolysis machine is mechanically designed and it is expected to greatly contribute to global entrepreneurship effort and benefit entrepreneurs who choose waste collection and management as their business.

The process is fully automated; shreds rubber and plastic before recycling them into usable products. Different terms can be used to describe the plant. Some of the most commonly used terms in continuous pyrolysis plants include; plastic to oil plant, waste rubber pyrolysis plant, plastic depolymerisation , plastic pyrolysis and many more.

The technology utilizes the most successful and user friendly approach that provide an effective solution to rubber and plastic waste management and recycling.

The continuous pyrolysis plant design coverts tires and waste plastic into carbon black, pyrolysis oil, and hydrocarbon gas. These are end products that can be used as industrial fuel to produce heat and steam electricity. The continuous plastic pyrolysis falls in the following categories:

(1)Tire pollution control equipment.

(2)Petrochemical.

(3)Renewable energy project.

(4)Waste to energy project.

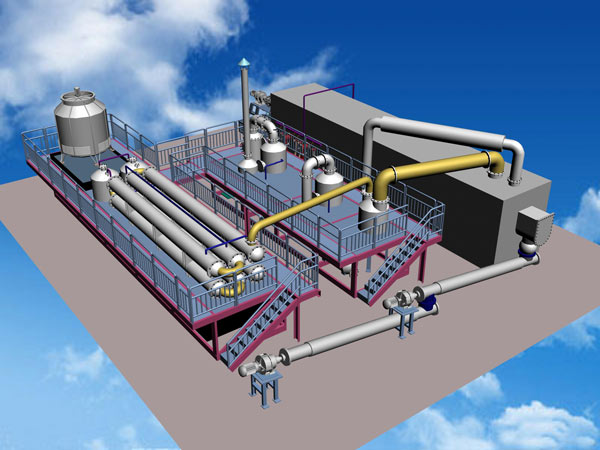

The large scale pyrolysis plant consists of machinery designing, equipment manufacturing, commissioning, simulations, technology transfer supply installation operational training and technology transfer. Get pyrolysis plant price here.

(1)Produces a pure and quality finished product.

(2)Uses green technology to achieve environmental friendly process.

(3)It utilizes both tires and plastics hence reducing soil pollution.

(4)It is a continues process that helps to keep the environment clean.

(5)It uses breakthrough technologies to improve the safety, profitability and makes operation easier.

(6)The machinery used in the process have non-moving parts meaning that it reduces the cost of maintenance.

(7)It does not require external fuel for heating.

The process starts by collecting all waste plastic and tires which are then moved to air lock feeding stage. After this, it undergoes pyrolisis resulting into oil vapor and carbon black. The two are then cooled to give useful byproducts. Oil vapor and gas undergoes fractional condensation to give pylolysis oil which is then taken through clarification and stabilization and stored as fuel. The fractional condensation process results in hydrocarbon gas that is stored and fired into fuel gases. Learn more information about small pyrolysis machine.