The global emphasis on recycling waste products has increased substantially over the last decade. Businesses around the world are reusing discarded products in unique and profitable ways. If you have thought about owning a pyrolysis plant to convert some of this material into burnable fuel, you are certainly not alone. One of the most abundant waste products on the planet is plastic. This can be in the form of plastic bottles and containers. These are often discarded into landfills. Whether you have access to these buried items, or if you own a municipal solid waste facility, processing plastic into burnable fuel is something that you should consider. Here is some basic information on how a standard plastic pyrolysis plant (planta de pirolisis de plastico) works.

The General Set Up Of A Plastic Pyrolysis Plant

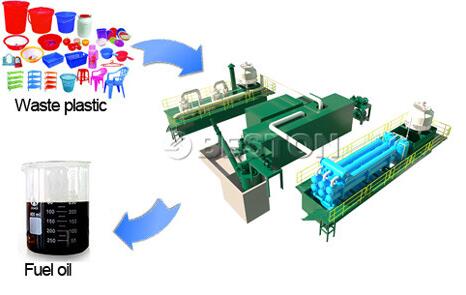

If you do invest in an entire pyrolysis plant, this will come with many different components. All of these are necessary for this process to work fluidly. You will begin by processing the plastic, chipping it down to a smaller size, so it can be placed in the pyrolysis reactor(planta de pirólisis). The evacuation of oxygen, followed by the heating of the plastic, will cause the plastic to break down without burning. The final product will be twofold. First, you will have a solid product which is charcoal. Second, you will have liquid products such as biofuel. Once this has gone through the reactor, it will then lead to containers where these materials can be stored. All of these components are necessary for a plastic pyrolysis plant to work.

How Do You Operate One Of These Plants?

These plants do require several human operators. Although most of it is automatic, people need to do certain things to keep things going. There will be individuals responsible for chipping up the plastic pieces. People will also have to remove the solid charcoal from the interior of the reactor(https://www.bestoneco.com/planta-de-pirolisis-de-lodo-aceitoso/). Others will be needed to package and store the charcoal and biofuel . However, the process itself is fully automated. It just needs to be managed and maintenance needs to be provided from time to time.

Where Can You Find Companies That Sell Them?

There are now many different companies that offer entire pyrolysis plants for sale. It has become a very large industry. To keep up with the demand, more companies have started investing in this industry. This has also allowed the prices of these plastic pyrolysis plants to come down significantly. They are designed for both small and large businesses. Whether you have access to a landfill or just a small amount of plastic at your facility, you can get one to accommodate these materials. These are listed online and by contacting them directly, it’s easy to get a quote (Beston Group China) on the total cost.

If you want to generate more revenue for your business, this is one of the best ways to utilize materials that you already have. If you do have access to a continual supply plastic or a landfill that you can begin to clean out, this can lead to a very profitable business venture. It may take some time to set up, but once this system is fully operational, it can lead to a very lucrative way of processing unwanted plastic for profit.