In the intricate web of the wood processing industry, a groundbreaking solution has emerged, ushering in a new era of sustainability and resource optimization: the sawdust to charcoal transformation. This innovative process not only tackles the perennial issue of sawdust disposal but also aligns seamlessly with the industry’s increasing need for eco-friendly alternatives.

The Conundrum of Sawdust

Wood processing, while essential, begets a substantial byproduct – sawdust. Traditionally viewed as a disposal challenge, sawdust has become the impetus for a groundbreaking solution. Enter the realm of sawdust to charcoal, a dynamic process that transcends waste into a valuable resource.

The sawdust to charcoal process of a sawdust charcoal making machine involves a meticulous conversion of sawdust, typically a byproduct of timber processing, into charcoal through controlled pyrolysis. Pyrolysis, a thermal decomposition process, transforms organic materials into charcoal in the absence of oxygen. This method not only curtails waste but also yields a high-quality charcoal product.

Key Advantages

- Waste Mitigation

Foremost among the advantages of sawdust to charcoal is waste mitigation. By repurposing sawdust, a traditionally burdensome byproduct, the process aligns with the principles of circular economy and sustainability. This waste-to-resource transformation not only reduces environmental impact but also optimizes resource utilization.

- Energy Efficiency

In the traditional scope of wood processing, sawdust is often treated as a redundant residue. The sawdust carbonization machine, however, enhances energy efficiency by converting this overlooked byproduct into a valuable energy source. The resultant charcoal can be used for heating, cooking, or even as a fuel in industrial processes.

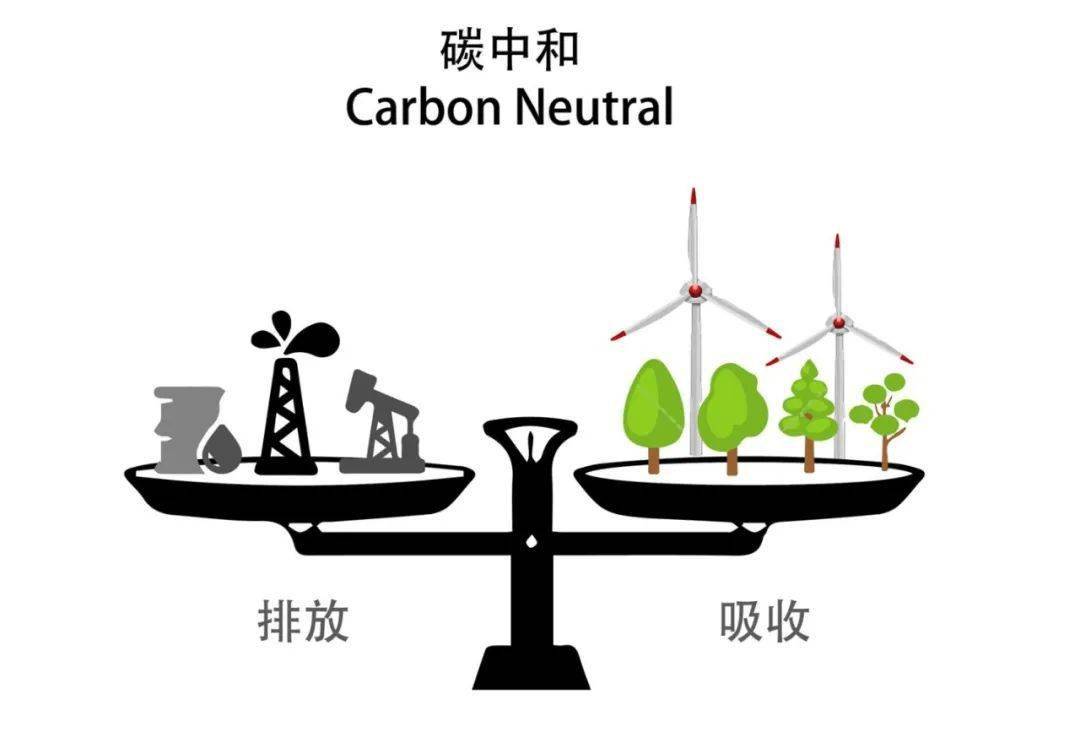

- Carbon Neutrality

The journey from sawdust to charcoal is not only economically viable but also environmentally conscientious. The carbon footprint of traditional waste disposal methods is substantially reduced through the adoption of this innovative approach. This carbon neutrality aligns with global efforts towards sustainable practices and climate responsibility.

Industry Integration

- Technological Integration

The marriage of technology and sustainability is evident in the sawdust to charcoal solution. Advanced pyrolysis technologies ensure an efficient and controlled conversion process, optimizing the yield of high-quality charcoal. This integration enhances the scalability and viability of the solution for diverse applications within the wood processing industry.

- Economic Viability

Beyond its environmental merits, sawdust charcoal machine underscores economic viability. By adding value to sawdust, businesses can diversify revenue streams and reduce waste management costs. The economic feasibility of this solution positions it as a strategic choice for wood processing enterprises seeking sustainability without compromising profitability.

Regulatory Landscape

- Compliance Imperatives

While the sawdust to charcoal solution presents a compelling case for sustainability, navigating the regulatory landscape is imperative. Compliance with environmental standards, waste management regulations, and emission controls is paramount to ensure the seamless integration of this innovative process into the wood processing industry.

- Certification Requirements

Achieving certification for the sawdust to charcoal process adds a layer of credibility to its adoption. Certifications attesting to the environmental soundness, product quality, and adherence to industry standards enhance the marketability of the charcoal produced through this sustainable approach.

Future Prospects

- Market Trends

As sustainability assumes a pivotal role in consumer choices, the market trends favoring eco-friendly products propel the sawdust to charcoal solution into the spotlight. The demand for responsibly sourced and produced charcoal is an opportune avenue for wood processing enterprises to differentiate themselves in a competitive market.

- Research and Development

The dynamic landscape of sawdust to charcoal invites ongoing research and development endeavors. Innovations in pyrolysis technologies, process optimization, and the exploration of new applications for the resultant charcoal contribute to the evolution of this sustainable solution.

Conclusion

In the crucible of the wood processing industry, the sawdust to charcoal solution emerges as a beacon of sustainability. Transforming a once-disregarded byproduct into a valuable resource, this process navigates the nexus of economic viability, environmental responsibility, and regulatory compliance. As industries increasingly pivot towards sustainable practices, embracing the potential of sawdust to charcoal is not just a choice; it’s a strategic imperative for a future where innovation and responsibility walk hand in hand. Ready to delve further into this subject? Visit Beston Group to discover more.