How To Start A Profitable Tire Recycling Business

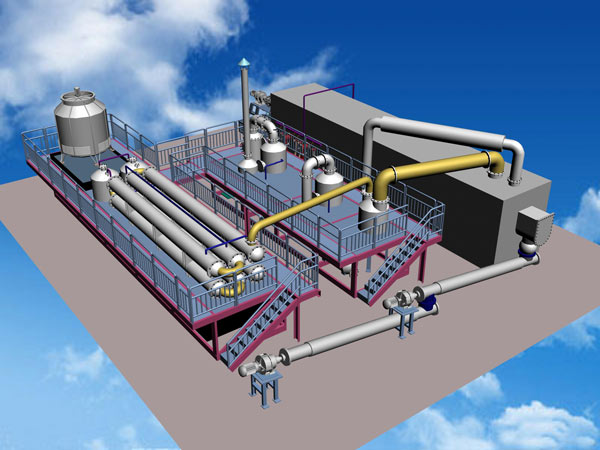

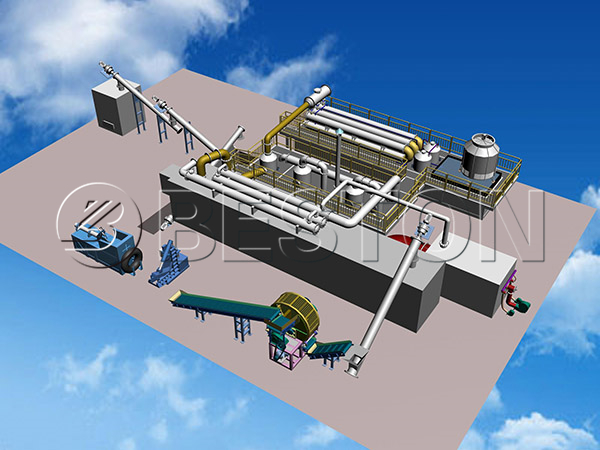

Tire recycling is a part of the recycling industry in which tire recycling businesses take old and waste tires and turn them into new products using pyrolysis technology that can serve as the raw materials needed for other processes in the civil engineering and industrial sectors. So tyre recycling plant is also known as tire pyrolysis plant. This kind of plant helps to ensure that the disposal process is eco-friendly, safe, saves resources and reduces waste. If you want to start a profitable tire recycling business, you will need to consider several factors:

- You will need a location to store the waste tires.

- A steady supply of waste tires.

- Basic understanding of how the tire recycling industry works.

- Any required state licenses and/or permits related to the tire recycling industry.

- Tire recycling business profit.

Tire Recycling Industry

The first thing that you will need to do is identify the potential demographic of the customer base that would possibly be interested in the materials that you are going to recycle, in this case, tires. By doing this, you will be able to determine the type of equipment you will need.

For example, you can use rubber tyre to create fuels that are derived from waste tires. You need to buy a tyre to oil plant. Recycled rubber, called carbon char, can also be used during the construction of running tracks and playgrounds. Selling the end products will make your business profitable. And there are many different types of tyre recycling equipment for sale on the market. What you need to do is to find the most suitable one.

Locating A Site

The next thing that you will need to do is find a rural piece of land or land in an area zoned for industrial use. You will need a location where you will be able to receive, store and recycle large numbers of waste tires safely.

Keep in mind that the environment around a tire recycling plant is very dusty and noisy due to the process of recycling these waste tires into raw materials. This means that there may be zoning and/or noise restrictions in the area where your business is located.

Also, the site you choose must also be able to offer trucks easy access to your site when they are collecting or delivering waste tire materials.

One more thing, the rubber oil plant will take up large space. The lower the space cost will reduce your investment cost. And lower costs will increase your tire recycling business profit. So choose a great site is important.

How To Set Up Your Tire Recycling Business

You will have to decide where to buy the tyre recycling equipment that you are going to use in your business. The main equipment is the pyrolysis machine. Also, you need dryer, tyre shredding machine, etc. A tire shredder that has several different types of screens will be able to create different tire crumb sizes that can be customized to meet the needs of your customers. More details can be found: https://bestonasia.com/tire-recycling-machine-for-sale/.

Running a profitable tire recycling business takes a lot of hard work. However, by keeping these tips in mind, you will be on your way to having a successful business.