The number of vehicles is increasing at a good pace all over the world. Among other things, this situation has also led to another big problem of huge piles of waste tires. It is estimated that millions of tires are thrown into landfills each year and this number is increasing every year. There are a number of problems of this approach.

One of the biggest problems is that these waste tires occupy a plot of land and the bigger problem is that the chemicals in these tires cause pollution as they leach into the ground. Thankfully, there is a way to get rid of these waste tires in a profitable manner.

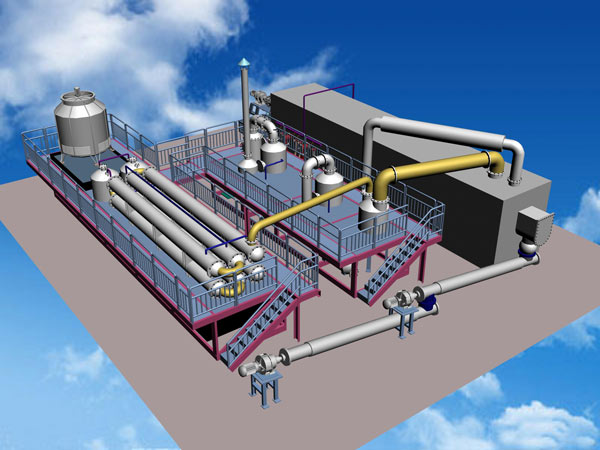

It can be done by converting the waste tires into useful fuel oil and various other products with the help of pyrolysis technology. For pyrolysis to take place, pyrolysis plant is required. There are two types of pyrolysis plant. One is the continuous pyrolysis plant and other one is the batch pyrolysis plant. Here is a list of some of the advantages of continuous pyrolysis plant.

Advantages of Continuous Pyrolysis Machine

As mentioned above, the other option available for pyrolysis plant is batch type plant. The biggest disadvantage of batch type plant is that it is low on automation and needs a lot of labor to be operated. Also, it is highly inefficient. After processing of every batch, the pyrolysis plant needs to be stopped to discharge the final products including steel wire and carbon black. Also, feeding the tires is not a continuous process and the processing needs to be stopped to fill up the plant again.

This whole process takes up to 20 hours which means the plant does not produce anything for a complete day. Another big disadvantage is that it cannot process high quantity of feed stock which means it is limited to processing only a limited amount of tires. Some of the most common batch processing pyrolysis plants have capacity of up to 12 tons of tires each day. This is great for personal business but a continuous pyrolysis plant is required where huge quantities of tires need to be processed on a regular basis. More choice: small scale pyrolysis plant.

One of the biggest advantages of continuous pyrolysis system for waste is that it has huge processing capacity as compared to the batch type plants. Most models available in the market are capable of processing up to 100 ton of waste tires each day. Another advantage of this plant is that it is fully automatic as it comes with its own feeding and discharge system for which the plant does not need to be stopped. Most of these plants come with multiple reactors which results in higher yield of oil from the raw material.

Overall, there are a number of advantages of continuous pyrolysis plants as compared to the batch type pyrolysis plant but it is important that you buy this plant only from a well-known manufacturer that has expertise in making these plants. There are a number of manufacturers making these plants but you should check their reviews and ratings before you decide to order this continuous pyrolysis plant from that. You can learn more here: https://kingtigergroup.com/fully-automatic-waste-tyre-pyrolysis-plant/.