Finding the Best Plastic Recycling Machines for Sale

Are you thinking about buying a plastic recycling machine? If you are, you will want to make sure that you purchase the best machine that you can. If you find a quality pyrolysis machine for sale, recycling the plastic that you have will be a breeze. These tips will help you to find some of the top plastic recycling machines for sale.

Find The Right Supplier

If you are going to be purchasing a recycling machine — or more than one machine — you will have to find a supplier that can give you what you need. Selecting the right supplier is very important.

If you choose your supplier well, you will be able to find out plenty of information about the machines you are considering. It will also be easy for you to have your new machines delivered to you.

Research Your Options

There are many different kinds of machines that are designed to recycle plastic. Not all of these machines work in the same way, and not all of these machines deliver the same kinds of results. You should try to look closely at your options as you work to make your decision.

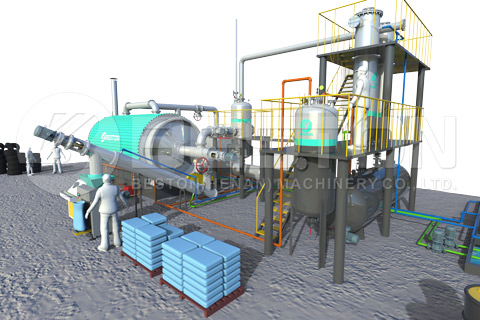

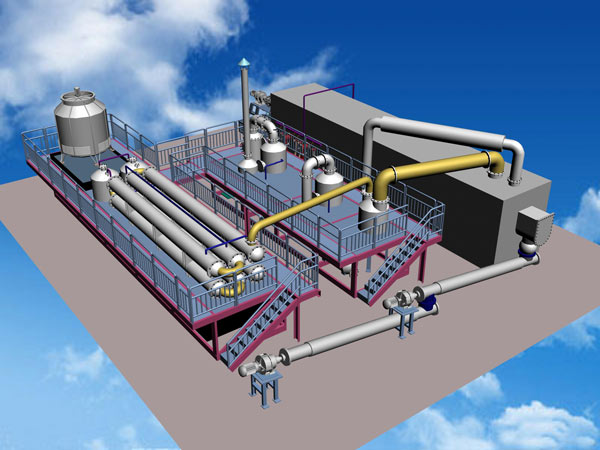

Find out what the pros and cons of various pyrolysis machines are. Don’t just look at the upfront cost; try to look beyond that. While you will have to pay for the machine that you buy, you will also have to cover the operational cost of pyrolysis plant. The cheapest machine isn’t always going to be the best choice. For example, there are small pyrolysis plant or continuous plant for sale. You need to choose a suitable one.

Find A Durable Machine

When you invest in a plastic recycling plant, you will want to know that that particular machine is going to last. The more durable a machine is, the better. Look for a machine that is made from strong and sturdy materials.

You should also make sure that the machine that you buy will be easy for you to maintain. If a machine requires a lot of maintenance, then you are going to have to put in a lot of energy if you want to keep it running properly.

Find A Machine That Fits All Of Your Needs

Think about what you want from a plastic pyrolysis machine for sale. You may want to put together a wishlist of some sort. You should think about what your ideal waste recycling machine would look like. More details can be found: https://wasterecyclingplant.com/.

This isn’t a decision that you have to rush. Take your time and look closely at various machines before you commit to buying them.

As long as you are willing to follow these suggestions, finding the best plastic recycling machines for sale shouldn’t be an issue for you. Take the time to track down a machine that you will be completely satisfied with. If the machine you buy works for you, then you will get a lot of enjoyment out of it.