The Best Method Of Getting Qualified Diesel From Waste Oil

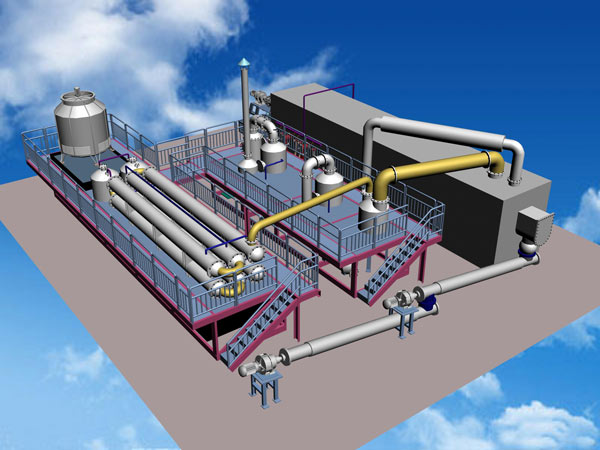

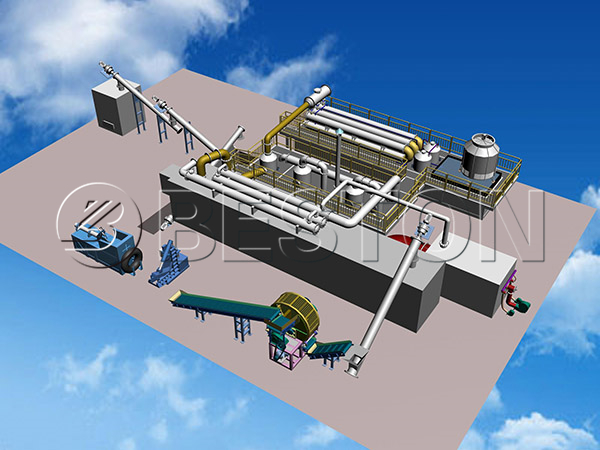

If you have ever brought waste oil to a transfer site, you might wonder what happens to that oil after it’s gone. Some people believe that it is actually buried into landfills, but most of it is actually reprocessed into oil that has been repurposed. It will go through waste plastic or tyre to diesel plant that will allow it to be purified. This will remove most of the impurities, and then it can be used for lubrication or it can also be converted into diesel fuel. Here is an overview of the best method for getting qualified diesel from waste oil provided by Beston Group China Machinery.

What Is Black Diesel?

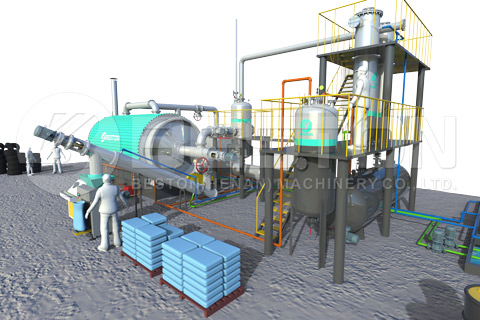

This is a type of diesel fuel that is not made from biodegradable materials. It actually comes from things like hydraulic oil, gear oil, and transmission fluid. Sometimes, the pyrolysis oil from plastic or tire to fuel plant can also be reprocessed into diesel fuel. This is all processed through machines that can clean the oil up, and then repurpose it for the use in diesel motors. It will burn just fine, and it’s actually dark in color which is why it is called black diesel. However, it is pure enough to be used by diesel engines, and it is also far less expensive. There are some people that say that it is not good for the diesel engines, but it is often used in some of the largest pieces of industrial waste oil distillation plant without any problems at all.

How To Find Machines That Create This Form Of Diesel Fuel

The machines that process this type of material are specifically designed to purify all of these forms of oil that are just sitting around. If you think about it, there are literally millions of gallons of used oil sitting at locations that are going to be there for many years to come. It can be sold at a very low price to these companies that can process it. Instead of it accidentally being spilled, or leaks occurring which will cause it to go into aquifers, it can be processed and used right away. The machines that do this can be purchased from companies that specialize in recycling machines that are found all over the world. Websites that sell industrial equipment of the best places to look. You can compare different businesses that sell them. If there are reviews, you can use that information to make your final choice if you want to.

Is This Something That Can Be Sold Easily?

According to most studies, this type of fuel is just as good as any type of diesel fuel that you would otherwise use. One of the primary concerns has already been mentioned. However, if you are a large trucking firm, or if you have industrial machines that a lumber mill, you will likely use this black diesel as a substitute. It could end up saving your company millions of dollars every year, and you will get the same amount of output from the diesel fuel that is produced. Similarly, if you just happen to do project like plastic to diesel machine, this kind of fuel can be very easy to get and then sold. It is also going to solve landfill problems, and leakage problems, which makes this a viable alternative that should be pursued by more companies that have access to this type of material.

It might not be the type of fuel that you may use in your vehicle, but there are thousands of businesses that do. If you are able to access this used oil, transmission fluid, and similar products, it can be repurposed for this reason. You will always have companies that are looking for this material to use with their diesel engines. It’s a cost-effective solution for many companies that are trying to find ways to continue their operations at a lower cost. There are also many crude oil refinery plant manufacturers around you and you can grasp this chance for making money now. Read more now if you’re interested: https://www.bestongroup.com/pyrolysis-plant-for-sale/.