With its wide range of uses, there is currently a very high demand for charcoal. However, given the impact traditional charcoal production has had on the environment, there has been an increased need for a greener and more efficient way to produce this valuable commodity. And this is where the sawdust charcoal making machine comes in. Through the process of carbonization, the sawdust charcoal-making machine is able to transform sawdust into biochar. This machine offers a cost-effective way of recycling sawdust (a waste material) and it also significantly increases its economic value.

How the Charcoal Making Machine Makes Biochar From Sawdust

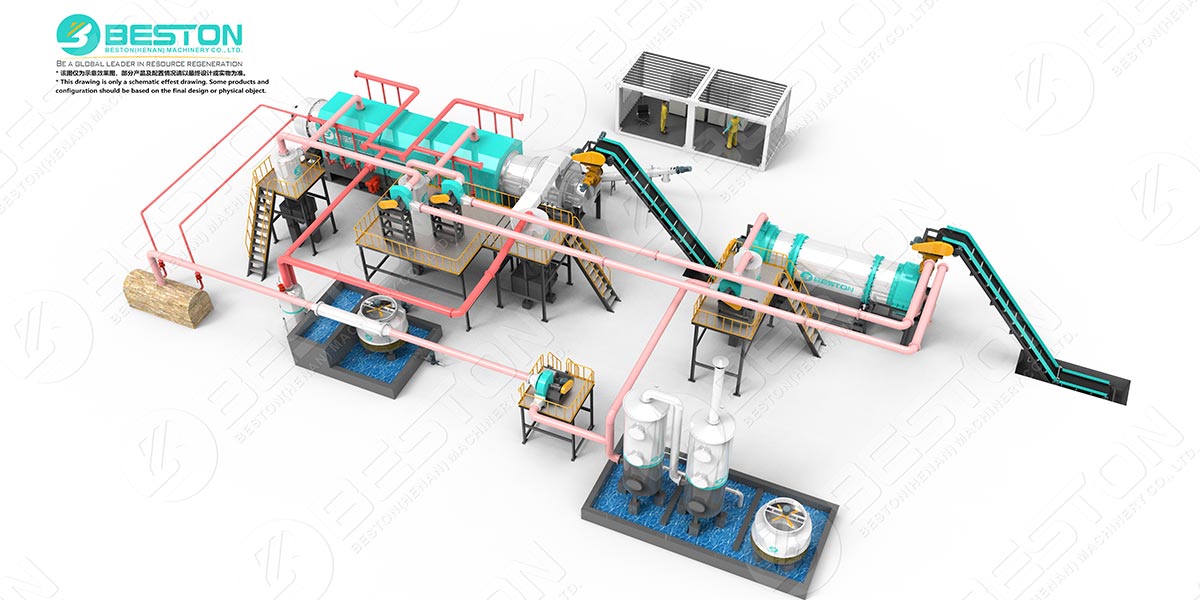

The charcoal making process using the sawdust charcoal making machine involves four main stages as discussed below:

(i) Pre-Treatment

The raw materials used (sawdust in this case) have to meet a certain standards to ensure optimal and quality charcoal production. The sawdust used should have a moisture content not more than 20%. So, it has to be passed through the dryer first for drying.

ii) High-Temperature Carbonization

Once the sawdust has been dried, it will be conveyed to the carbonization furnace. Here, the saw dust will be heated under high temperatures in an oxygen-free environment. Sawdust charcoal production starts at around 300 degrees celsius. Combustible gas will also be produced in the process. The production of charcoal in an oxygen-free environment under high temperatures achieves high-quality charcoal with a high calorific content. The charcoal produced contains more than 80% charcoal. This type of charcoal will burn for much longer than traditional charcoal. More information on charcoal machine here.

This stage involves the production of the other by-products of the sawdust charcoal making machine: tar and vinegar. The smoke produced in the carbonization furnace contains wood tar and wood vinegar. To obtain these products and minimize smoke emissions, the sawdust charcoal-making machine comes equipped with a condensation tower and separating tank. Both by-products are recovered through these devices.

The combustible gas will be passed through the dedusting spray system which will eliminate the sulfur contained in the gas. This gas can then be collected or redirected and used as a source of fuel for the carbonization chamber.

iv) Charcoal Cooling and Collection

The charcoal produced will be too hot to be collected, and since natural cooling may take some time, the sawdust biochar machine has a cooling system that lowers the charcoal temperature to around 30 degrees celsius which is much easier to handle.

Applications of the Final Products of the Charcoal Making Machine

Besides charcoal, the sawdust charcoal making machine allows you to obtain three other valuable and useful products. These are combustible gas, wood vinegar, and tar. All of these products have a wide range of uses as you will see below.

Charcoal, the main product of the sawdust charcoal making machine, is commonly used as a fuel for domestic and industrial heating purposes. It is also used in the agricultural sector as a fertilizer.

Combustible gas is often used to heat the small charcoal making machine and can also be collected and used as a source of fuel for domestic and industrial purposes. It is also used in electricity generation.

Tar is used as a key raw material in the chemical industry as well as the shipbuilding industry.

Wood vinegar can be used as a food preservative and it is also an important ingredient in the drug making industry.