Tyre Pyrolysis Plant: A Sustainable Solution For Energy Development

The world is currently grappling with an unprecedented energy crisis that demands urgent action towards sustainable solutions. In this quest for a greener future, the tyre pyrolysis plant emerges as an innovative and environmentally-friendly approach that not only addresses the energy crisis but also tackles the growing issue of tyre waste disposal.

Understanding Pyrolysis Technology

Definition and principles of pyrolysis

At the core of tyre pyrolysis plant lies the principle of pyrolysis – a process of thermal decomposition without oxygen. When subjected to high temperatures, the complex hydrocarbons present in discarded tyres break down into simpler compounds, yielding valuable end-products.

Pyrolysis process in Waste Tyre Pyrolysis Plants

In tyre pyrolysis plant, the pyrolysis process involves feeding shredded tyres into a reactor chamber. The reactor is then heated to a specific temperature, causing the tyres to vaporize and release volatile gases. These gases are then condensed into liquid fuel, commonly known as pyrolysis oil or tyre oil.

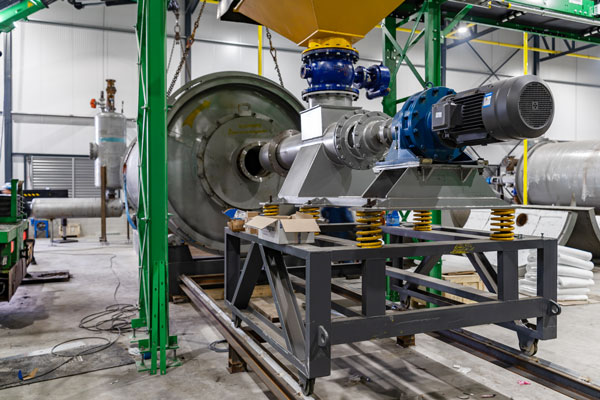

Key components of a Tyre Pyrolysis Plant

A tyre pyrolysis plant comprises several vital components that play a crucial role in its efficient operation. The reactor, condenser, oil storage tanks, and gas recycling system are the key elements that contribute to the overall effectiveness and output of the plant.

Environmental Benefits of Tyre Pyrolysis

Reducing landfill waste and environmental pollution

The improper disposal of used tyres poses significant environmental challenges. Stockpiled tyres not only contribute to landfill waste but also serve as potential fire hazards and breeding grounds for pests. By diverting tyres from landfills and converting them into valuable products, tyre pyrolysis plants help alleviate the burden on the environment.

Mitigating greenhouse gas emissions

Traditional tyre incineration releases harmful greenhouse gases, which exacerbates climate change and contributes to air pollution. Embracing tyre pyrolysis plant significantly reduces carbon emissions, as the process is carbon-neutral and does not add to the overall greenhouse gas concentration in the atmosphere.

Preserving natural resources

The energy produced through pyrolysis plant for sale is a sustainable alternative to fossil fuels, which are finite and non-renewable. By decreasing reliance on conventional energy sources, we can conserve precious natural resources and promote a more sustainable energy landscape.

Energy Recovery and Utilization

Types of energy produced through pyrolysis

Tyre pyrolysis plants generate three primary types of energy products: pyrolysis oil, carbon black, and syngas. Each of these by-products has unique properties and can be harnessed for diverse applications.

Methods of energy recovery from pyrolysis products

The pyrolysis oil obtained from the process can undergo further refinement to produce higher-grade fuels, including gasoline, diesel, and jet fuel. Carbon black, on the other hand, finds valuable applications in the rubber manufacturing industry. Additionally, the combustible syngas can serve as a fuel source for power generation.

Applications of pyrolysis-derived energy

The versatility of pyrolysis-derived energy makes it suitable for various industrial applications. From powering machinery in manufacturing facilities to fueling vehicles and even producing electricity, the energy products obtained from tyre to oil plant find widespread use across different sectors.

Economic Viability and Incentives

Cost-effectiveness of Tyre Pyrolysis Plants

Investing in tyre pyrolysis plant can prove economically advantageous in the long run. The revenue generated from selling pyrolysis oil, carbon black, and syngas, combined with reduced waste management costs, enhances the economic viability of these projects.

Government incentives and policies supporting pyrolysis projects

Governments worldwide recognize the potential of tyre pyrolysis plants in achieving sustainability goals. To encourage the adoption of this technology, many governments offer financial incentives, tax benefits, and subsidies to support pyrolysis projects.

Investment opportunities in the pyrolysis industry

As the demand for sustainable energy solutions grows, the pyrolysis industry presents lucrative investment opportunities. Entrepreneurs and investors looking to contribute to a greener future can explore the prospects offered by tyre pyrolysis plant. Therefore, when investing in machines, you need an experienced manufacturer to provide you with a professional ROI analysis. That’s what Beston Group can do.

Conclusion

The tyre pyrolysis plant represents a sustainable and forward-thinking solution for addressing the energy crisis while simultaneously tackling the pressing issue of tyre waste. By harnessing the power of pyrolysis, we can pave the way for a greener, more energy-secure future. Embracing this innovative technology is not only economically beneficial but also essential for creating a sustainable and eco-conscious world. Through concerted efforts and strategic investments, tyre pyrolysis plant can play a pivotal role in building a cleaner and more prosperous future for generations to come.