Manage Waste Products More Effectively With A Waste Sorting Equipment

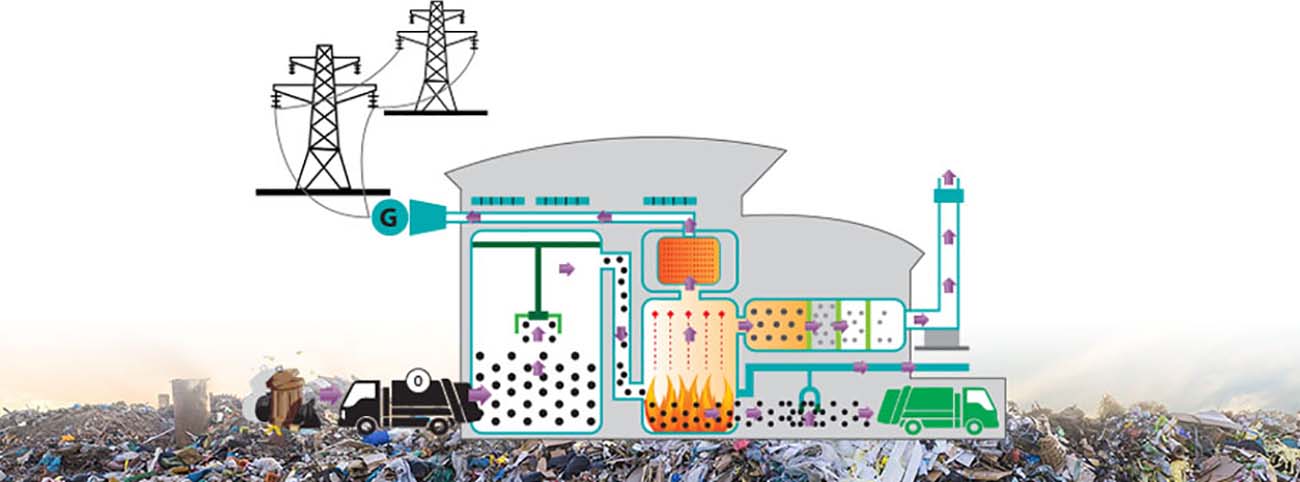

Stop for a minute and think about how much garbage you throw out each day. Even if you are aware of your waste habits, you most likely still have to throw away a lot of plastic containers, product packaging, old papers, tin cans, and other items. Now, imagine everyone else in your city throwing away a similar amount of garbage. When you add it all together, it adds up to a tremendous amount of waste. The municipal solid waste sorting machine is a good option for recycling these waste. Besides, the egg tray machine is a good way to recycle paper waste. See egg tray machine manufacturers.

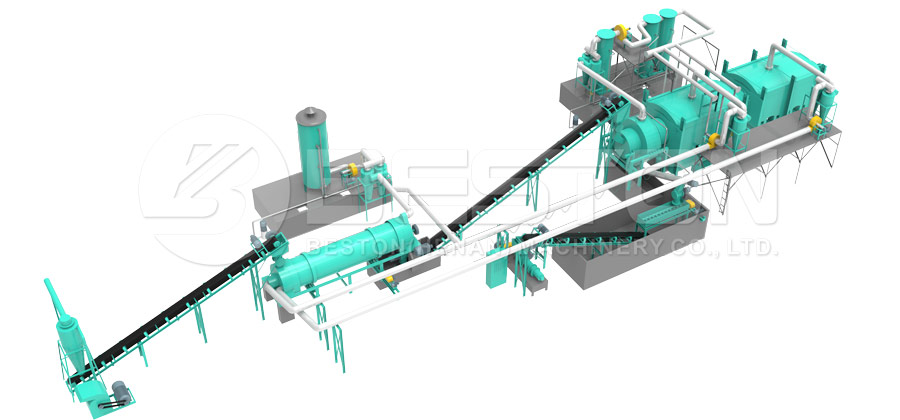

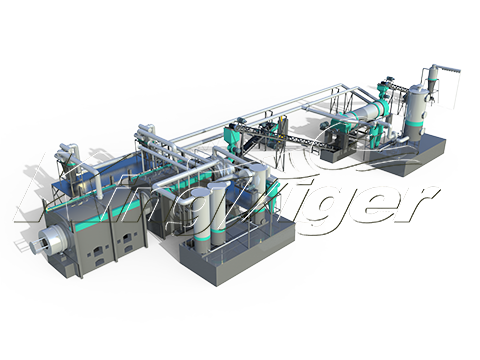

Managing that much waste requires innovative thinking and modern-day tools. Fortunately, today’s municipal solid waste sorting machines are more advanced than ever. They do an excellent job of sorting garbage, removing recyclable materials from the items that truly need to be thrown away.

Machines like these can vary in terms of their size and design. For the most part, however, they automate the waste sorting process, requiring very little human interaction. This makes it possible to process a large volume of waste relatively quickly.

Typically, the process starts with a bag-breaking machine. This machine is designed to break up the plastic bags that are holding the garbage. This not only allows the waste to be sorted more effectively but it also allows the bags themselves to be included in the sorting process. There is a good channel for you to get other waste to energy machine https://bestonmachinery.com/pellet-machine-for-sale/price/.

As the waste makes its way through the machine, it passes through a variety of different sorting mechanisms, each designed to separate the trash into different categories. For instance, one part of the machine is designed to remove any cardboard or paper products from the waste stream.

Another part is designed to capture any glass that was thrown away. The glass that is recovered can be recycled, allowing it to be turned into new products again. This helps keep it out of the landfill, which is good news for the environment.

Plastic is also separated using these machines. The process of separating plastic from other types of waste is one of the most advanced parts of the sorting process. Usually, it relies on special lasers. These lasers are used to identify the various grades of plastic so that they can be sorted into the right piles for recycling. Or you can process plastic by this machine.

Metal is also extracted from the waste through the use of magnets. These powerful magnets are used to grab and remove any type of magnetic metal from the waste stream. Since aluminum is not magnetic, it usually is removed using an eddy-current separator.

All in all, municipal waste sorting equipment like these are extremely effective at reducing the amount of waste that is thrown away. As the population continues to grow, innovations like these are essential. Managing waste responsibly is an important part of caring for the environment and ensuring that the planet stays beautiful and unharmed for future generations. Buy this kind of machine from this reputable manufacturer Beston Group Henan.