Enhancing Carbon Removal Projects with dMRV for Biochar

Biochar carbon removal projects are gaining momentum as part of global efforts to combat climate change. Through pyrolysis, organic materials such as biomass are converted into biochar, a stable form of carbon that can be stored in soil for centuries, helping to sequester carbon dioxide (CO₂) from the atmosphere. To ensure the integrity and effectiveness of these projects, advanced monitoring, reporting, and verification (MRV) systems are essential. One such system is dMRV (digital Monitoring, Reporting, and Verification), which leverages technology to enhance the efficiency, transparency, and accuracy of carbon removal claims in biochar projects.

1. The Role of dMRV in Biochar Carbon Removal

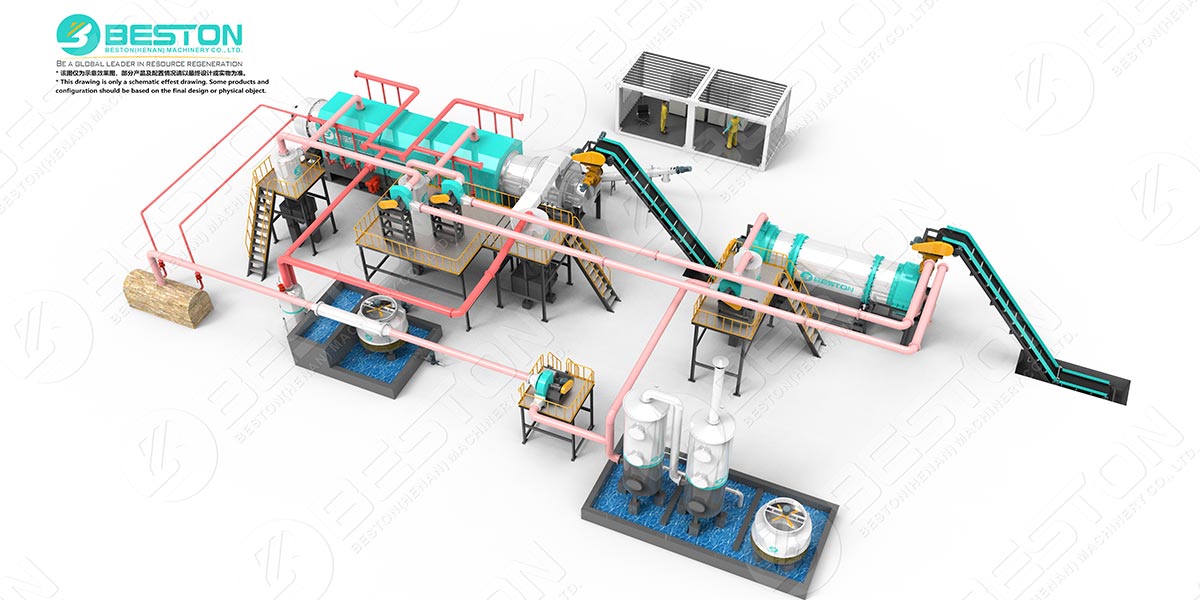

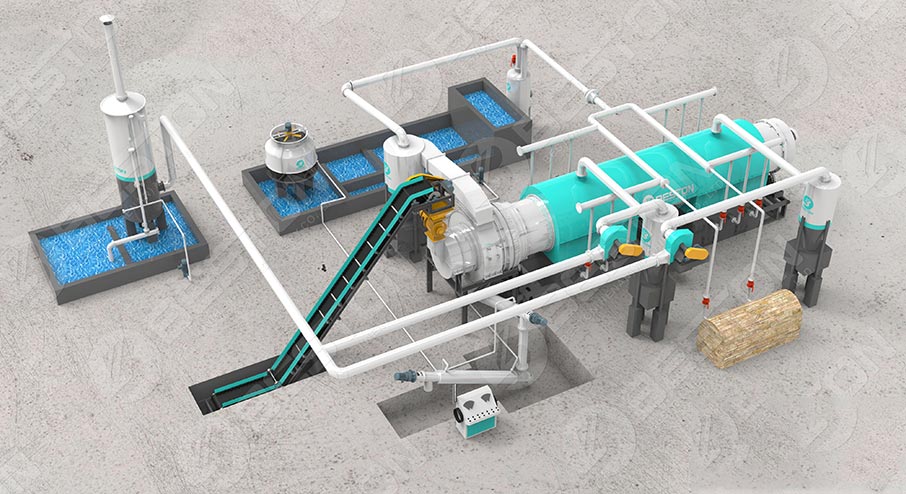

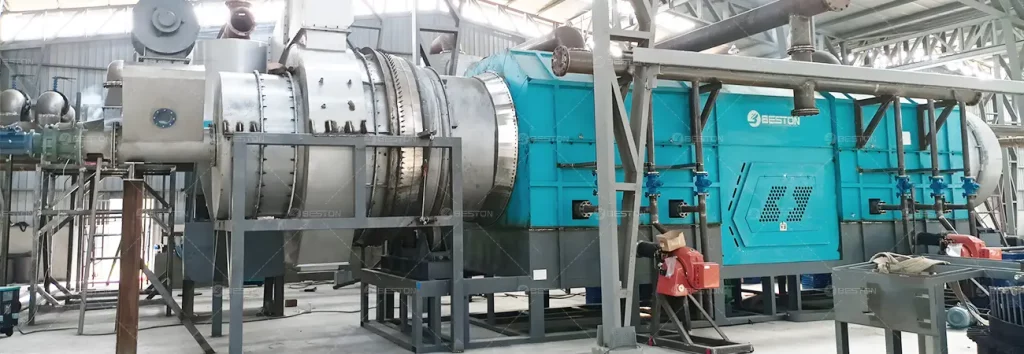

dMRV refers to the integration of digital tools and technologies to monitor, report, and verify carbon removal activities in real-time. In the context of a biochar machine, dMRV enables precise tracking of carbon sequestration through biochar production, offering a more reliable and transparent means of assessing the carbon removal achieved by the project. By using sensors, data loggers, and automated systems, dMRV enhances the overall credibility of carbon removal projects, particularly in industries where accurate carbon credits are crucial.

Real-Time Data Monitoring

One of the most significant advantages of dMRV is the ability to collect real-time data from the pyrolysis plant. Using IoT (Internet of Things) sensors and digital tools, operators can track key performance indicators (KPIs) such as temperature, pressure, feedstock quality, and biochar yield. These metrics are essential for determining the efficiency of the pyrolysis process and the overall carbon sequestration rate. Real-time monitoring allows for prompt adjustments, ensuring that the process operates within optimal conditions, and maximizing the potential for carbon removal.

Transparency and Data Integrity

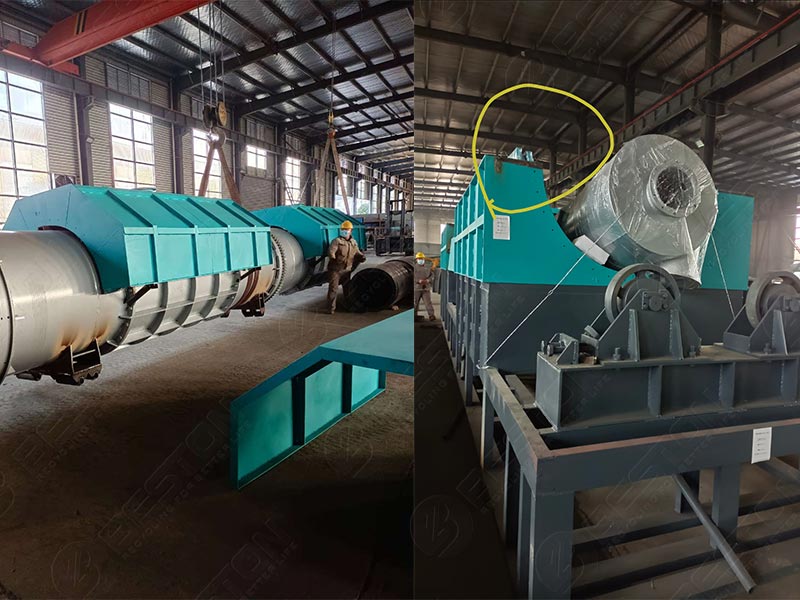

In the carbon markets, the credibility of carbon credits relies on verifiable data. Traditional MRV systems often involve manual data entry, which is prone to human error and fraud. dMRV addresses this challenge by automating the data collection and reporting process, significantly improving the accuracy and transparency of carbon removal claims. Digital systems create an immutable record of the process of biochar reactor, which can be audited by third-party verifiers, ensuring the data’s integrity and building trust in the project’s results.

2. Optimizing Carbon Credits in Biochar Projects

The carbon credits generated by biochar carbon removal projects are an essential component of the global carbon trading market. These credits represent a verified amount of CO₂ removed from the atmosphere and are tradable on various platforms. However, the process of generating credible and verifiable carbon credits requires rigorous reporting and verification, which can be resource-intensive. dMRV simplifies this process by automating the measurement, reporting, and verification of carbon sequestration, thus streamlining the creation of carbon credits.

Efficient Reporting

dMRV systems automatically compile data from the biomass pyrolysis plant, reducing the need for manual reporting and increasing the speed at which carbon credits can be generated. The system can calculate the total amount of carbon sequestered in the biochar, generate reports, and submit them to certification bodies or carbon credit registries. This efficiency helps project developers reduce operational costs while ensuring timely and accurate carbon credit issuance.

Scalability and Automation

The scalability of dMRV makes it an ideal tool for large-scale biochar projects. By implementing digital technologies across multiple pyrolysis plants or facilities, project developers can automate and standardize carbon removal reporting at scale. This allows for more extensive carbon credit generation, making the project more financially viable and contributing to global efforts to reduce greenhouse gas emissions. Additionally, the use of dMRV allows for the integration of various carbon offset protocols, enabling projects to access different carbon markets and maximize their impact.

3. Ensuring Compliance with Standards and Regulations

As the demand for carbon credits increases, so does the scrutiny on the methodologies and standards used to measure and verify carbon removal. The dMRV system ensures that biochar carbon removal projects comply with international standards such as those set by the Verified Carbon Standard (VCS), Gold Standard, or other recognized carbon certification bodies. By providing consistent, transparent, and verifiable data, dMRV helps projects meet regulatory requirements, making them eligible for carbon credit certification.

Enhanced Auditability

One of the challenges in the carbon credit market is ensuring that emissions reductions are permanent, measurable, and real. dMRV enhances auditability by providing real-time, verifiable data, making it easier for third-party auditors to assess the project’s compliance with carbon offset standards. This reduces the likelihood of disputes or discrepancies and increases the confidence of stakeholders in the carbon credits being generated. Contact Beston Group for reliable biochar production solutions.

4. The Future of Carbon Removal Projects with dMRV

As global efforts to tackle climate change intensify, the demand for reliable carbon removal solutions continues to grow. Biochar production via pyrolysis offers a promising method of sequestering carbon, and the integration of dMRV systems is crucial for scaling up these projects and ensuring their success. The continued evolution of digital technologies, such as AI, blockchain, and IoT, will further enhance the capabilities of dMRV, making it an even more powerful tool in the fight against climate change. By increasing the transparency, accuracy, and scalability of carbon removal projects, dMRV will play an essential role in enabling the widespread adoption of biochar as a climate solution.