How to Find the Best Pellet Making Machine

Are you thinking about investing in a new pellet making machine? If so, you need to prepare yourself for quite a bit of research. Despite what many people would have you believe, buying this piece of equipment entails comparing multiple manufacturers, looking at specifications, and asking for the best prices. All this takes time and effort, so you shouldn’t rush your decision if you want to make the most out of your investment. In this guide, you’ll learn some of the most important things to keep in mind when buying a pellet making machine.

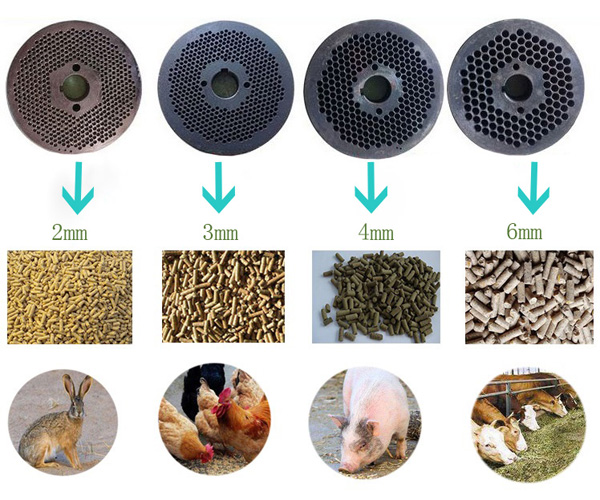

The first thing you need to do is determine what time of pellet machine you need for your company. Some of the most popular machines include wood pellet machines, rice husk pellet machines, biomass pellet machines, and straw pellet machines. All of them virtually work identically, but you need to know which one to get depending on your unique applications.

Regardless of which machine you need, you must choose a reliable manufacturer. It’s easy to find manufacturers of pellet machines these days. All it takes is to open up your internet browser and search for suppliers or vendors. However, not all of them are worth your time and money. You can’t expect to find the most reliable manufacturer in just a few clicks. Instead, be ready to do your due diligence as you would have to compare several suppliers. In general, it’s ideal to talk to at least three of them.

By talking to more than one supplier, you get the opportunity to compare their products, prices, and customer service. Pellet machines from different brands might look the same, but there might be subtle differences that could impact your decision. If you’re not knowledgeable about the ring die wood pellet machine, then ask the manufacturers to clear up any questions you may have. This also allows you to see whether they know what they’re talking about.

Of course, you must factor in your budget as well. But remember that this shouldn’t be the biggest factor to influence your decision. It helps to set a budget before you even begin shopping. Doing so allows you to narrow down your list right away. It also helps you avoid the temptation of buying a machine that comes with specifications you won’t ever need or use.

A good practice is to compare similar products from several vendors and look at their corresponding price tags. You might be surprised that some of them cost much higher than the others. This isn’t necessarily an indication that the higher-priced biomass pellet equipment is better in all aspects. For this reason, you need to be careful when doing your comparison shopping. Make sure that the machine comes with the right specifications while still falling within your budget.

These are some of the most important steps you need to take if you want to find the best pellet making machine for your company. You can’t afford to take any shortcuts. Do your due diligence so you can end up with a pellet machine that you can use for years to come. Get in touch with Beston (Henan) Machinery Co. ltd..