Tyre and Plastic Waste’s Liquid Eco-Black Gold through Pyrolysis

In the quest for sustainable solutions to manage the ever-growing mountains of waste, the transformative process of pyrolysis has emerged as a beacon of hope. Particularly, the conversion of tyre and plastic waste into liquid gold through pyrolysis showcases a remarkable innovation in waste management. This post explores the journey from discarded tyres and plastics to eco-friendly liquid output, delving into the intricacies of waste pyrolysis plant and its potential to turn waste into a valuable resource—eco-black gold.

Understanding Pyrolysis

Pyrolysis, derived from the Greek words “pyro” meaning fire and “lysis” meaning separating, is a process that involves the thermal degradation of organic materials in the absence of oxygen. This lack of oxygen prevents combustion and leads to the breakdown of complex molecules into simpler compounds. In the context of waste management, pyrolysis provides a unique avenue to convert discarded materials, such as tyres and plastics, into valuable liquid products.

The Tyre and Plastic Waste Dilemma

Tyre and plastic waste pose significant environmental challenges, from land and water pollution to the release of harmful chemicals. Traditional disposal methods often involve landfills or incineration, contributing to greenhouse gas emissions and environmental degradation. Pyrolysis offers a sustainable alternative by transforming these challenging waste streams into liquid outputs that can be further utilized.

The Liquid Gold Output: Pyrolysis Oil

At the heart of the eco-black gold narrative lies pyrolysis oil, a liquid output derived from the thermal decomposition of tyre and plastic waste. This oil is a versatile substance with applications ranging from fuel production to chemical feedstock. The quality and composition of pyrolysis oil depend on factors such as temperature, residence time, and the type of feedstock, presenting opportunities for customization based on specific needs. Know the pyrolysis machine cost when you are related to this business.

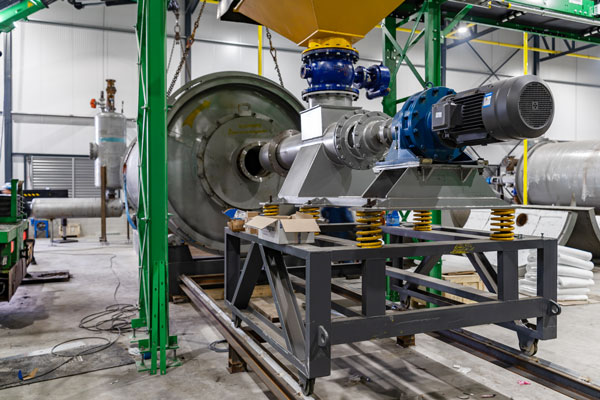

Technological Advances in Tyre and Plastic Pyrolysis

Advancements in pyrolysis technology have played a pivotal role in optimizing the conversion of tyre and plastic waste into high-quality pyrolysis oil. Innovative reactor designs, process control systems, and integrated refining techniques have enhanced the efficiency and scalability of the pyrolysis process. These technological strides are critical in making waste-to-oil conversion economically viable and environmentally sustainable.

Environmental Impact and Sustainability

The environmental benefits of tyre and plastic pyrolysis are multifaceted. By diverting waste from landfills and incineration, the process mitigates the release of harmful pollutants and reduces the carbon footprint associated with conventional waste disposal. Additionally, the production of pyrolysis oil can serve as a sustainable alternative to fossil fuels, contributing to the global effort to transition towards cleaner and greener energy sources.

Economic Opportunities and Job Creation

The eco-black gold industry not only addresses environmental concerns but also presents economic opportunities. The establishment and operation of tyre and plastic pyrolysis plants create jobs in waste collection, facility management, and downstream industries that utilize pyrolysis oil as a feedstock. This economic ripple effect can contribute to community development and regional growth.

Applications of Pyrolysis Oil

Pyrolysis oil finds application in diverse industries, making it a valuable commodity in the market. As a fuel, it can be used for heat and power generation, replacing traditional fossil fuels. In the chemical industry, pyrolysis oil serves as a feedstock for the production of various chemicals and materials. Its versatility positions it as a key player in the transition towards a circular economy.

Challenges and Considerations

Despite the promising potential of eco-black gold, challenges exist in the widespread adoption of tyre and plastic pyrolysis. Technical challenges, regulatory frameworks, and market dynamics all influence the scalability and acceptance of this innovative waste-to-oil process. Addressing these challenges is crucial for unlocking the full potential of pyrolysis in managing tyre and plastic waste sustainably. The tyre pyrolysis plant manufacturers will show more information to investors.

Global Initiatives and Success Stories

Around the world, initiatives and success stories highlight the positive impact of tyre and plastic pyrolysis. From large-scale industrial operations to community-driven projects, these endeavors showcase the adaptability and effectiveness of pyrolysis in diverse settings. Examining success stories provides insights into best practices, lessons learned, and the potential for scalability on a global scale.

Future Prospects and Innovations

The eco-black gold journey is far from over, with ongoing research and innovations poised to further enhance the efficiency and sustainability of tyre and plastic pyrolysis. From improved catalysts to novel reactor designs, the future holds exciting possibilities for advancing this waste-to-oil technology. The integration of pyrolysis into broader waste management strategies could revolutionize how societies approach the handling of waste streams.

Conclusion

In the dynamic landscape of waste management, the conversion of tyre and plastic waste into eco-black gold through pyrolysis stands as a testament to human ingenuity and environmental responsibility. As we strive for a more sustainable and circular economy, the eco-black gold narrative represents a beacon of hope, showcasing how innovative technologies can turn challenges into opportunities. From the ashes of discarded tyres and plastics rises a liquid resource that not only mitigates environmental impact but also fuels the journey towards a greener and more sustainable future.