How To Find The Right Tyre Shredder For Sale

The tyre shredder is a great investment in any recycling operation. This machine takes waste tires and shreds them so they can be used in a pyrolysis plant. All tires and rubber need to be shredded or they won’t work in the machine, so a good tire shredder is essential. Read on to learn how to find the best tyre shredder for sale (trituradora de neumaticos en venta) so you can find exactly what you need to run your business.

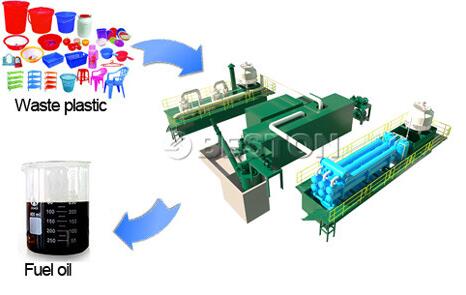

The tire shredder is efficient and it can hold tons of tires. It shreds them fast so you don’t have to worry about waiting for this machine to do its job. You can quickly shred tons of tires so they are ready to be turned into oil in the pyrolysis plant.

Waste tires can easily produce thousands of gallons of oil and this oil can be sold or even refined into gasoline. The price of the shredder is affordable and they come in multiple sizes so you can easily find the size that is going to be the best fit for your needs.

If you are ready to purchase the machine from Beston (Henan) Machinery Co. ltd. you need to think about how many tons of tires you want to shred at one time. You will need to have this information when you are ordering the machine. The manufacturer can also help you find the best machine so you get exactly what you need.

This machine is a great investment in your business and it can help you make more money. You can run the tires through the oil machine or you can even just shred the tires and sell them. The machine gives you plenty of options since it is so easy to use.

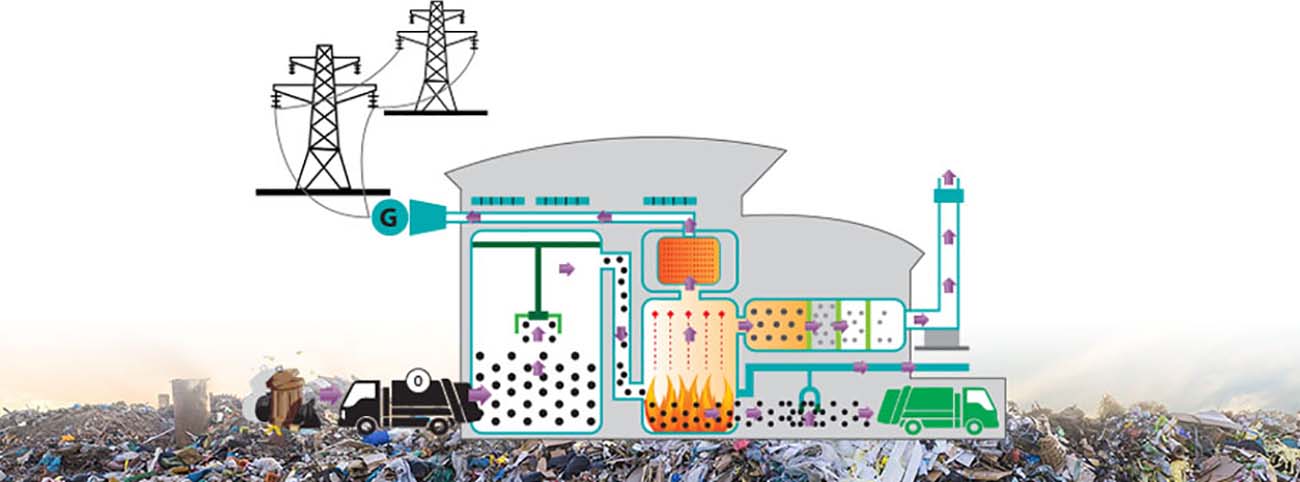

Each machine has anti-pollution devices that ensure that no pollution is going to escape into the environment. The machine is very easy to use and it is also equipped with all of the latest safety features that make the machine safe and efficient to run. This machine is a great investment for a business of any size and it can help you make a lot of money.

If you want your business to be more efficient and you want to ensure you make as much money as possible you need to invest in this machine. The price is affordable and the machine will ship all over the world so you can get a great price on it no matter where in the world your business is located: https://www.bestongroup.com/es/pyrolysis-plant-for-sale/.

The manufacturer can help you find the best price on a tyre shredder for sale and they also offer training and a variety of after-sales services that give you peace of mind when you buy this machine for the pyrolysis process (proceso de pirolisis de neumaticos). If you want to ensure that you get the best price on the machine you need to ensure that you choose this machine from a manufacturer you can trust. There are multiple models available and it will be easy to choose the machine that is the best fit and price for all of your needs.